Anything that can possibly go wrong, does - Epigraph of The Butcher: The Ascent of Yerupaja (1952) by John Sack

Failure Modes and Effects Analysis (FMEA) is the most underrated technique and process for designing, manufacturing and delivering high quality products and services. Effective FMEAs should be an integral part of product and process development and quality management systems. When done well FMEAs can lead to trouble-free products, process excellence, low warranty costs, and high levels of customer satisfaction. In light of the benefits of FMEA, we believe that FMEAs should be used as often and as widely as possible.

As important and effective as FMEAs (Design, Process, Equipment..) are FMEAs tend to be static documents (most often put together in Excel) and hard to rely for active implementation of recommended actions for risk reduction (RPN).

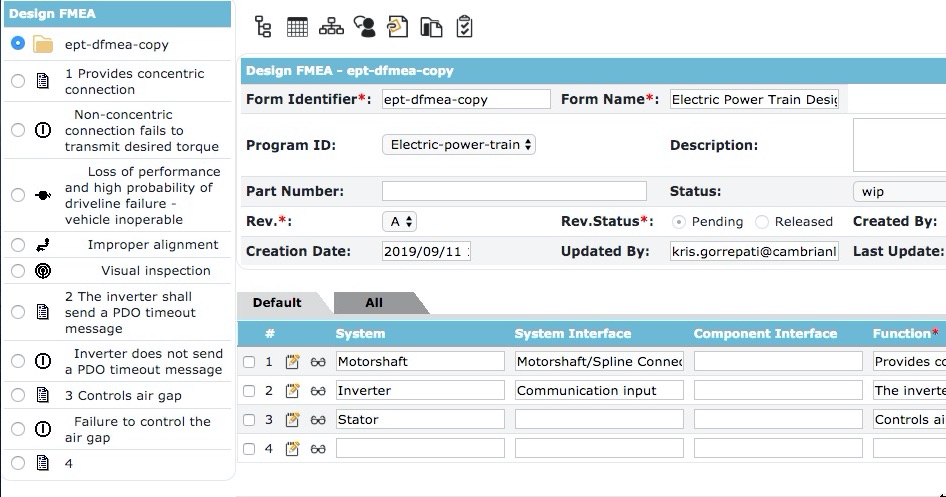

KaizenKit offers a unique approach for FMEA(s) by allowing cross-functional teams to work collaboratively on FMEAs. Secondly, KaizenKit makes FMEA a living document by supporting dynamic workflows for recommended actions to ensure completion and verification of the effect of recommended actions.